How to Distinguish Between CPO and OIO? What Is Their Fundamental Difference?

Original Article by SemiVision Research

Recently, many people have been asking me about the fundamental difference between CPO and OIO. When a new technology is being discussed and promoted, concepts and terminologies often get confused and misused. However, as the industry matures, these concepts will gradually become more standardized..

1. The Literal Difference Is Only a Surface-Level Distinction

CPO: Co-Packaged Optics

The literal translation is Co-Packaged Optical Module.

The key defining term here is "Co-Packaged", meaning that CPO is defined from a packaging perspective in the optical module domain.

OIO: Optical I/O

The literal translation is Optical Input/Output.

It refers to the use of optics for chip input and output.

In a data chip system, optical connectivity requires a physical optical module. Therefore, OIO can also be extended to mean an optical module used for I/O functions.

This term is often contrasted with Electrical I/O (EIO). From an application perspective, OIO describes optical connectivity methods.

2. Summary of Differences

CPO and OIO are both related to optical modules, but they differ in definition scope.

CPO is defined from a packaging perspective, while OIO describes optical connectivity methods.

Due to their different dimensions of definition, their applications may partially overlap.

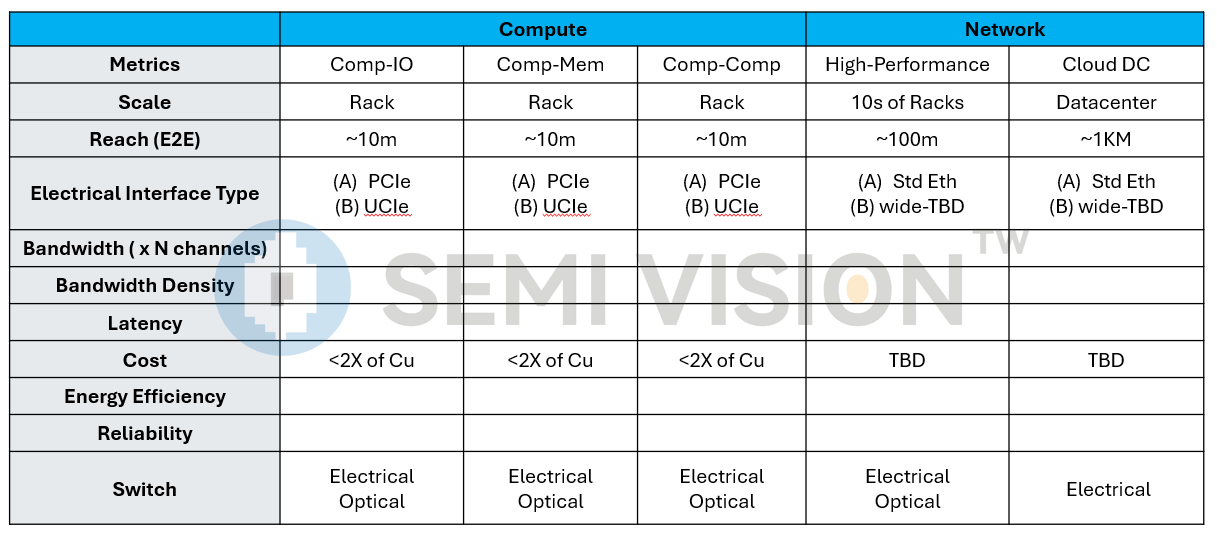

In this classification diagram from Microsoft , optical interconnects are divided into two main categories: computing and networking. This classification is quite accurate and provides a fresh perspective, especially for those of us with a telecommunications background.

One category is computing, which means that this type of optical interconnect is used as part of the computing process. Since it is considered an integral part of computing, it can be associated with GPU computing power, making it a component of AI computing infrastructure. As AI continues to rise, it will drive the development of the OIO industry chain, which in turn will promote the widespread adoption of CPO.

The other category is networking, which doesn’t require further elaboration.

In this classification, the computing-related optical interconnects primarily refer to the connection between compute and memory. Since these connections are an essential part of computing, they impose strict requirements on latency, power consumption, and coherence, making distance control a key consideration.

The Fundamental Difference Lies in Parameters: Power Consumption and Latency

When it comes to differences in parameters, the key distinguishing factors between computing-class OIO and networking-class optical interconnects are power consumption and latency. To illustrate this, we refer to a requirements table from Microsoft (MS).

According to this table:

Computing-class OIO has a transmission distance of 10 meters, whereas network-class optical interconnects can reach 100 meters to 1 kilometer.

Latency for computing and HPC applications must be under 5 nanoseconds, excluding fiber delay, while latency for data cloud networks can go up to 20 nanoseconds.

Power consumption also varies significantly between these two categories.

The data from Microsoft’s requirements table serves as a reference, but in reality, the performance metrics achieved by companies like Ayar Labs and NVIDIA surpass these figures.

What Lies Behind the Fundamental Differences?

The key factors behind the parameter differences discussed earlier are the differences in implementation approaches, which in turn stem from historical reasons.

For CPO , the concept was introduced by Microsoft and Facebook to address the power consumption issues of pluggable optical modules in data centers. Essentially, CPO competes with pluggable optical modules. Since it follows the standards of pluggable optical modules, it must comply with industry specifications such as DR, FR, and SR.

On the electrical link level, chip pin fan-out is limited, and switch SerDes speeds have been evolving through 28G, 56G, 112G, and 224G.

At the 51.2T switch stage, CPO operates at 112G/lane using PAM4 modulation.

At the 102.4T switch stage, it scales up to 224G/lane using PAM4.

The capacity increase is achieved by increasing SerDes speeds.

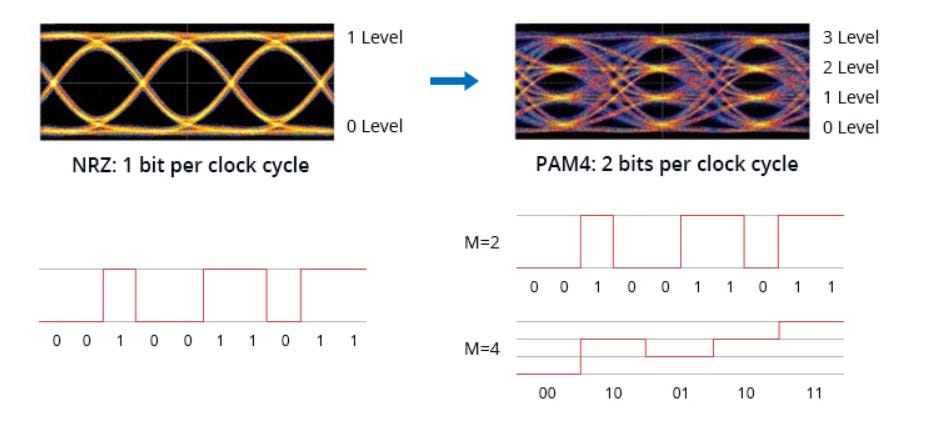

What is PAM4?

With the rapidly growing demand for network traffic, 400G transmission solutions have been continuously introduced. Among them, PAM4 (4-level Pulse Amplitude Modulation) has emerged as a widely adopted high-speed interconnect technology for next-generation data centers. It plays a critical role in 400G Ethernet, facilitating both electrical and optical signal transmission.

Advantages of PAM4 Over NRZ

Higher Data Transmission Efficiency

With PAM4, each symbol carries 2 bits, effectively doubling the data rate compared to NRZ, which only carries 1 bit per symbol.

This means that PAM4 can achieve the same data transmission capacity at half the symbol rate of NRZ, reducing the required bandwidth.

Reduced Transmission Loss

Because PAM4 operates at half the symbol rate of NRZ, the signal experiences lower channel loss, improving transmission efficiency over long distances.

Optimized Bandwidth Utilization

PAM4 increases network bandwidth without requiring additional fiber deployment, making it an efficient solution for 400G Ethernet and beyond.

OIO’s Advantage: Free from Historical Constraints

In contrast, OIO does not carry these historical burdens. Instead, it focuses on internal data transfer within the switch, where speeds currently range from 16G to 32G.

OIO can directly synchronize with the parallel data bus inside the switch, eliminating additional conversion steps.

Total bandwidth can be expanded through different optical wavelengths, meaning that bandwidth scaling within a certain range has no energy cost, which is a significant advantage.

Implementation Benefits and Power Efficiency

In practical implementations, NRZ optical signals require a much lower extinction ratio compared to PAM4, which results in:

Lower drive voltage

Lower overall power consumption

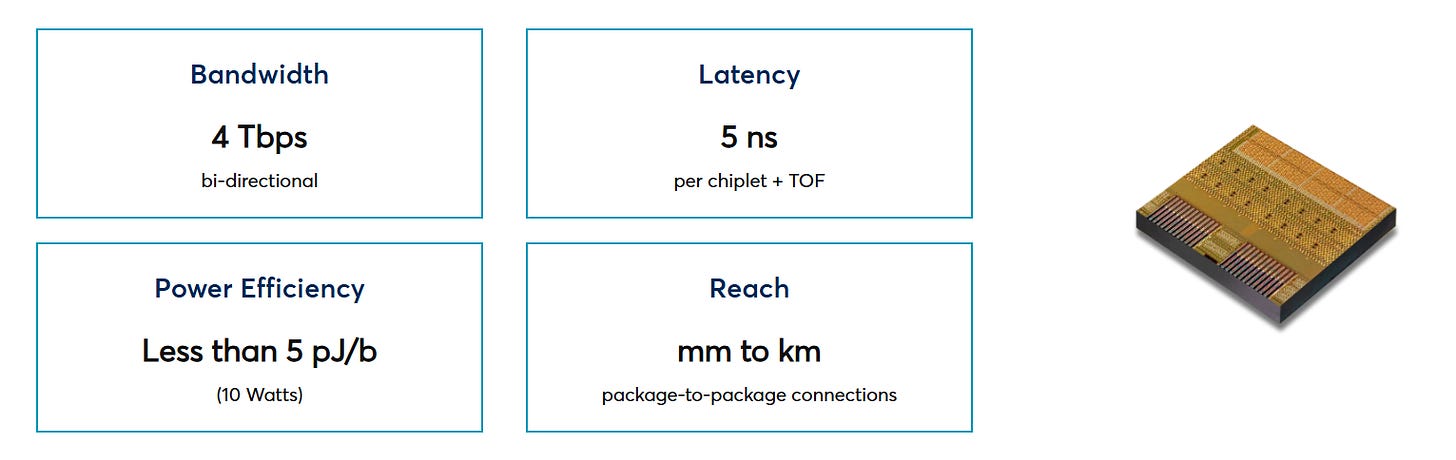

As a result, the mainstream approach today is the 32G × 8-wavelength solution, as adopted by Ayar Labs, which easily achieves a power consumption of just 5 pJ per bit.

TeraPHY™ Optical I/O Chiplet Optimized for AI: Industry-First Optical I/O Chiplet

In imec’s Optical I/O evolution roadmap, the EIC (Electronic-Photonic Integrated Circuit) power consumption can reach an astonishingly low 0.125 pJ per bit

TSMC CPO Specifications Analysis

Paid Subscribers Area will provide full table of

Classification of Compute and Network

TeraPHY First-Generation Chiplet Performance

imec OIO System Targets

TSMC CPO Specifications Analysis