Toward Self-Sufficiency: China’s Equipment Development Strategy

Original Article by SemiVision Research

SEMICON China Launches: Chinese Semiconductor Equipment Players Showcase Emerging Technologies

SemiVision Research shares noteworthy developments from the floor

Huawei’s 5nm Hope?

Mysterious Provider— Chip Equipment Firm to Unveil “阿里山 (Alishan)”

Chinese semiconductor equipment manufacturer SiCarrier (新凱來), which is reported to have close ties with Huawei, is set to debut a range of new products at SEMICON China. Whether the company will present 5nm-compatible equipment has drawn considerable attention.

SiCarrier’s new product lineup is uniquely named after famous Chinese mountains, including:

• Epitaxy system “峨眉山 (Emei Mountain)”

• Etching systems “武夷山 (Wuyi Mountain)”

• Chemical Vapor Deposition (CVD) system “長白山 (Changbai Mountain)”

• Atomic Layer Deposition (ALD) tool “阿里山 (Alishan, TW)”

While the company’s patent portfolio has garnered interest, its ability to achieve mass production and integrate a robust supply chain remains an open question. Advanced chip manufacturing requires coordinated breakthroughs across lithography, materials, EDA tools, and other domains.

“China’s development of ALD and related technologies may have ripple effects beyond semiconductors, influencing sectors such as optical coatings and consumer applications,” said a SemiVision Research “This is something Taiwan must watch closely.”

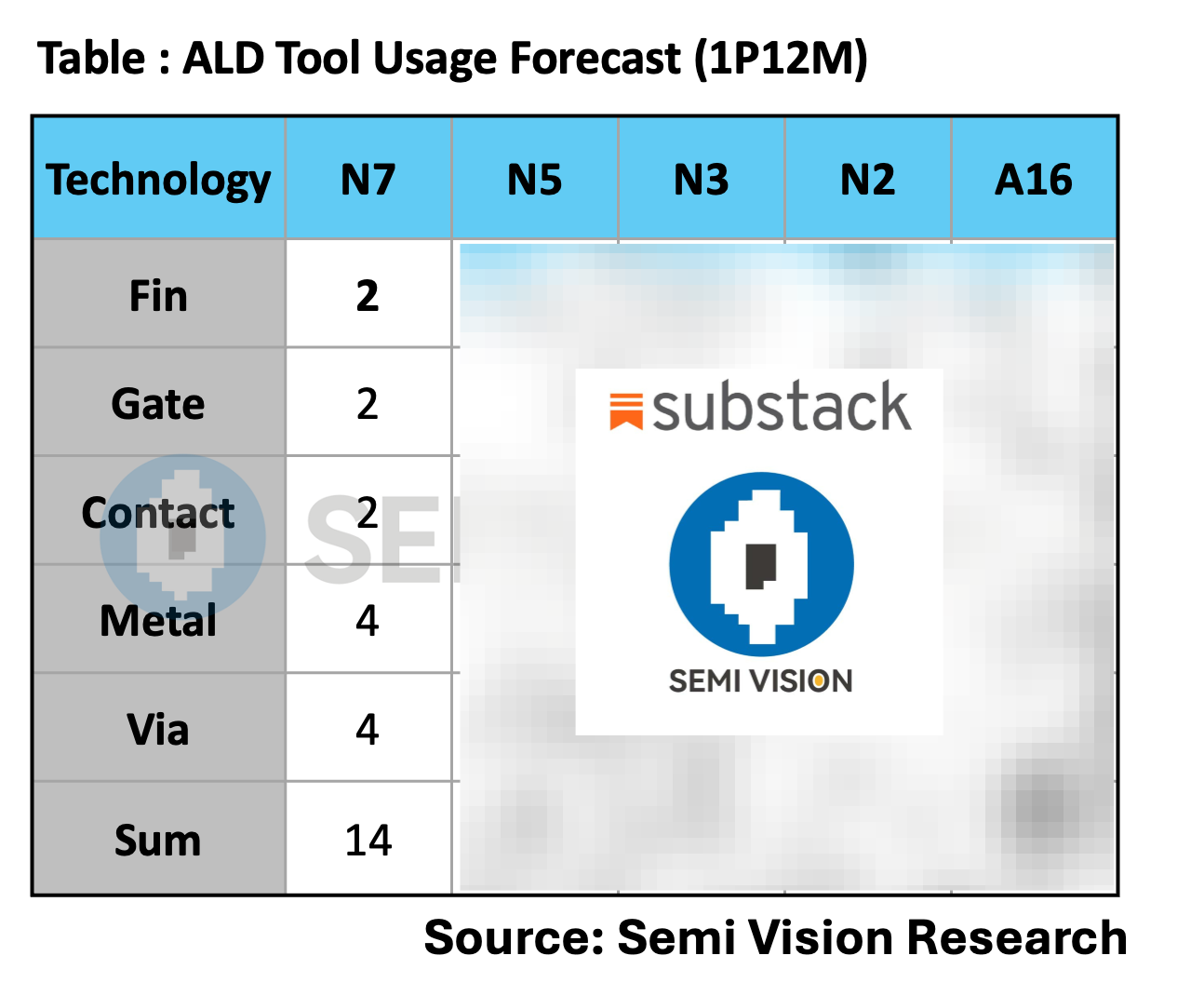

ALD: A Critical Enabler for Advanced Nodes

According to SemiVision Research, ALD has become a critical step in advanced semiconductor processes. In thin-film deposition, there are two main categories: oxide layers and metal layers. Traditionally, PVD (Physical Vapor Deposition) has been used for metal deposition. However, as feature sizes shrink and aspect ratios grow, ALD (Atomic Layer Deposition) is increasingly essential due to its atomic-level precision and conformality.

Physical Vapor Deposition (PVD) and Atomic Layer Deposition (ALD) are two of the most critical thin-film deposition techniques in semiconductor manufacturing.

PVD remains a cost-effective, high-throughput option for conventional metal deposition in legacy and mid-range nodes. But as device geometries shrink and 3D architectures proliferate, ALD is indispensable for its uniformity, precision, and compatibility with FinFET, GAA, and heterogeneous integration.

For sub-5nm nodes and future chip architectures, ALD will continue to be favored despite its complexity and higher cost.

Major Global ALD Equipment Supplier

Huawei Patent on SAQP: Toward DUV-based 5nm Manufacturing?

According to the China National Intellectual Property Administration (CNIPA), Huawei Technologies Co., Ltd. filed a patent in September 2021 titled “Method for Manufacturing Semiconductor Device Using Self-Aligned Quadruple Patterning” (Publication No. CN117751427A).

The patent describes a technique leveraging Self-Aligned Quadruple Patterning (SAQP) to etch multiple dense lines on a silicon wafer, thereby increasing transistor density and enhancing chip performance. This method is aimed at enabling 5nm-class chip manufacturing using deep ultraviolet (DUV) lithography, reducing dependence on EUV tools.

The South China Morning Post previously reported that SiCarrier, backed by the Shenzhen municipal government, gained attention in 2023 after acquiring a patent related to 5nm manufacturing using DUV. The company is speculated to be a key technology provider behind Huawei’s Mate 60 Pro smartphone, which launched in 2024 with a 7nm chip despite U.S. export controls.

SiCarrier maintains a low public profile. Its official website only notes that it is a subsidiary of Shenzhen Major Industrial Investment Group, founded in 2021—coinciding with tightened U.S. sanctions on Huawei. The site lists only four entry-level semiconductor tools, with no information on executive leadership or company ownership.

Recently, the company published its first official WeChat article, announcing its participation in SEMICON China and claiming its role as a “core semiconductor equipment supplier” committed to the “development and manufacturing of advanced semiconductor tools.”

For Paid Members, SemiVision Research will discuss following topics:

The Competitive Landscape of Semiconductor Equipment: Global Leaders vs China’s Rise

SiCarrier’s “Mountain Series” Semiconductor Equipment: Strategic Deployment for Advanced Node Manufacturing

Restructuring the Fab Equipment Ecosystem: Global Incumbents vs. China’s Contenders

SiCarrier Core Equipment Highlights

SiCarrier Metrology & Inspection Strategy

SiCarrier Breakthroughs in Metrology & Inspection